So for the next step, we had to ask round about how to use the silicon material. This was because we would have to learn how to work with it. First, we learned that it needs a mould to let the mix of silicon to become solid. We tried two types of moulds. We first worked with silicon mould but it needs too much time even though it gave a very good shape. The second one was using the clay which worked relatively well.

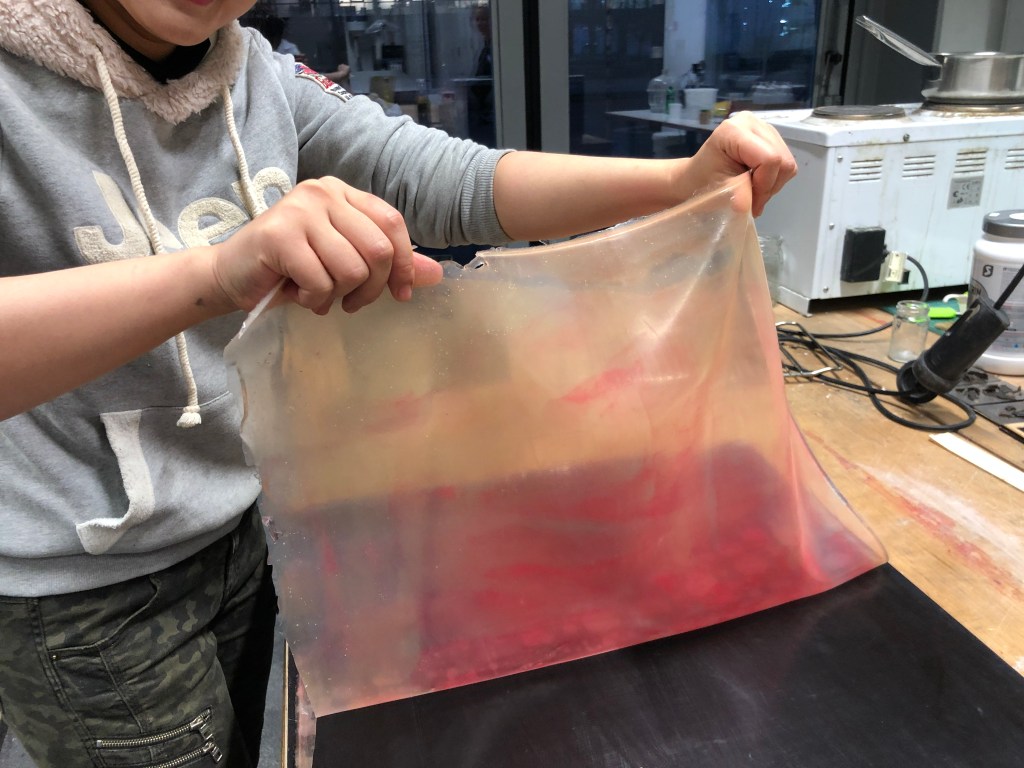

The problem was putting too much color inside of the silicon mix. Which too much color, the silicon became very sticky and oozy. Also, it wasn’t transparent enough to show the LED lamps. Therefore, we had to figure out a right proportion of the silicon mix and the color. As we had to produce Silicon in a shot amount of time, we had to see whether if it is not available for the next day. That’s why we tried our best to make it as accurate as possible.

The mentoring regarding the silicon object was pretty nice, and we ha fun working with the new material. It’s just a bit frustrating that we had to figure out the way how to deal with this material and I was not sure if we could use silicon for the final prototype following the other trials as the cost was very high.

After making the tentacles with silicon, we tried to integrate the lights inside of our suit. Also, to have a dominant atmosphere, we created the cape with silicon as well. Aesthetically it was very interesting to try the things out, and we liked how it worked as a wearable. It was also a good opportunity for us to try out the mixture of fabric and silicon.